Trending...

- FrostSkin Launches Kickstarter Campaign for Patent-Pending Instant-Chill Water Purification Bottle

- The New Monaco of the South (of Italy)

- RZ Logistics Launches Redesigned Website to Start the New Year

Kaltra's new one-piece manifold technology removes former limits of large microchannel water coils, enhancing reliability for data centers, AHUs, and free cooling systems.

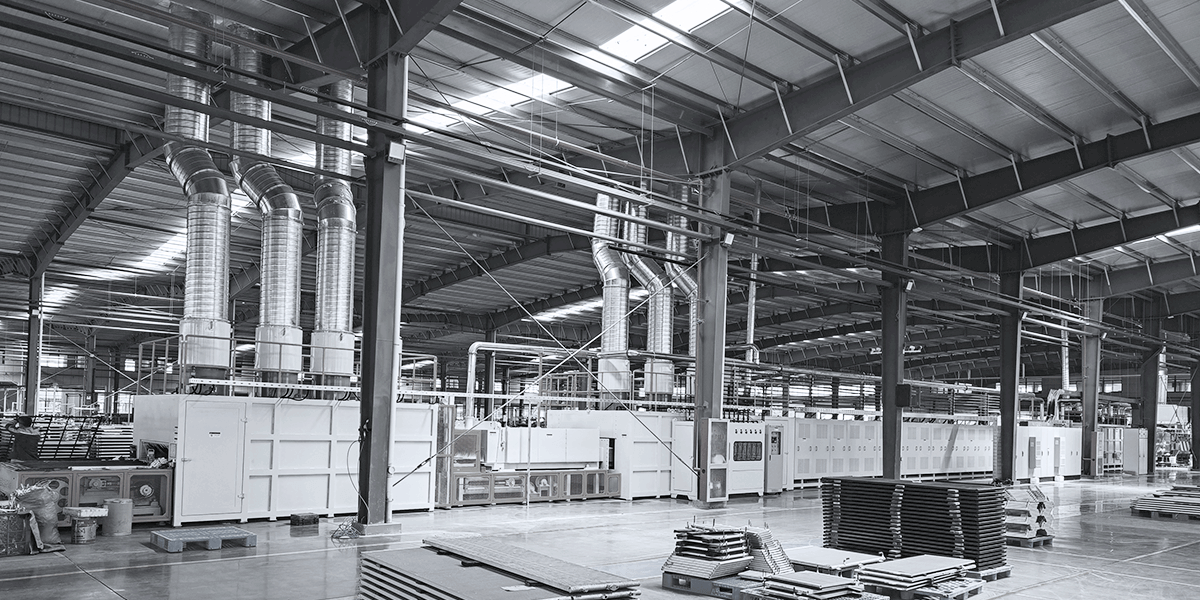

ALTMUNSTER, Austria - nvtip -- With the commissioning of a fully automated tube-processing station capable of cutting and punching the complete range of manifold tubes up to 2400 mm in length, Kaltra can now supply microchannel coils equipped with solid, one-piece manifolds. This capability is particularly valuable for large microchannel water coils, where seamless manifolds significantly increase structural robustness, reduce assembly time, and lower overall production cost.

Beyond manufacturing efficiency, one-piece manifolds offer notable engineering advantages. By eliminating welded joints along the manifold length, the risk of leakage is reduced, pressure integrity is improved, and long-term reliability is enhanced.

More on nvtip.com

The launch of the tube-processing station represents the final step in Kaltra's transition to a fully integrated production line for large microchannel coils. Earlier, the company expanded its manufacturing capabilities by installing large-conveyor CAB furnaces, enabling reliable brazing of oversized heat exchangers and paving the way for large-MCHE production.

Historically, large-format microchannel water coils faced constraints in demanding environments—especially in data center applications, where they are used as AHU coils and free cooling coils, and where absolute reliability is essential. With the introduction of solid, one-piece manifolds and full-scale large-MCHE production technology, these limitations have now been fully removed.

As a result, Kaltra's customers gain access to a new class of high-capacity, highly reliable microchannel fluid coils suitable for the most demanding and mission-critical cooling applications.

To date, Kaltra provides the widest nomenclature of tubes and components for microchannel water coils among all manufacturers. This allows the company to deliver tailored solutions that precisely match OEM requirements, ensuring optimal thermal performance, reliability, and integration across diverse applications.

Beyond manufacturing efficiency, one-piece manifolds offer notable engineering advantages. By eliminating welded joints along the manifold length, the risk of leakage is reduced, pressure integrity is improved, and long-term reliability is enhanced.

More on nvtip.com

- Adam Clermont Releases New Book – Profit Before People: When Corporations Knew It Was Dangerous and Sold It Anyway

- "Big Tech is Not Talking About Everyone Owning, Controlling & Monetizing Their Own Data in the AI Future, but Phinge is," Says its CEO Robert DeMaio

- Dirty Heads, 311, Tropidelic, and The Movement to Headline Everwild Music Festival in 2026 with its largest lineup to date!

- The Stork Foundation Announces 2025 Year-End Impact and Grant Awards Amid Rising National Demand

- Stout Industrial Technology Appoints Paul Bonnett as Chief Executive Officer

The launch of the tube-processing station represents the final step in Kaltra's transition to a fully integrated production line for large microchannel coils. Earlier, the company expanded its manufacturing capabilities by installing large-conveyor CAB furnaces, enabling reliable brazing of oversized heat exchangers and paving the way for large-MCHE production.

Historically, large-format microchannel water coils faced constraints in demanding environments—especially in data center applications, where they are used as AHU coils and free cooling coils, and where absolute reliability is essential. With the introduction of solid, one-piece manifolds and full-scale large-MCHE production technology, these limitations have now been fully removed.

As a result, Kaltra's customers gain access to a new class of high-capacity, highly reliable microchannel fluid coils suitable for the most demanding and mission-critical cooling applications.

To date, Kaltra provides the widest nomenclature of tubes and components for microchannel water coils among all manufacturers. This allows the company to deliver tailored solutions that precisely match OEM requirements, ensuring optimal thermal performance, reliability, and integration across diverse applications.

Source: Kaltra GmbH

Filed Under: Business

0 Comments

Latest on nvtip.com

- Custom Home Builder Connecticut Valley Homes Wins 2025 Home of the Year from the Modular Home Builders Association

- Scoop Social Co. Partners with Air Canada to Celebrate New Direct Flights to Milan with Custom Italian Piaggio Ape Gelato Carts

- Breakout Phase for Public Company: New Partnerships, Zero Debt, and $20 Million Growth Capital Position Company for 2026 Acceleration

- Japan's Patented "Hammock'n" Smartphone Band Targets Hand Fatigue From Long Phone Use

- Reditus Group Introduces A New Empirical Model for Early-Stage B2B Growth

- CCHR: Harvard Review Exposes Institutional Corruption in Global Mental Health

- IoT Marketing to Officially Launch Tech Scope Connect at CES After Party

- Goatimus Launches Dynamic Context: AI Prompt Engineering Gets Smarter

- Global License Exclusive Secured for Emesyl OTC Nausea Relief, Expanding Multi-Product Growth Strategy for Caring Brands, Inc. (N A S D A Q: CABR)

- RNHA Affirms Support for President Trump as Nation Marks Historic Victory for Freedom

- American Laser Study Club Announces 2026 Kumar Patel Prize in Laser Surgery Recipients: Ann Bynum, DDS, and Boaz Man, DVM

- Lineus Medical Completes UK Registration for SafeBreak® Vascular

- Canyons & Chefs Announces Revamped Homepage

- $140 to $145 Million in 2026 Projected and Profiled in New BD Deep Research Report on its Position in $57 Billion US Marine Industry; N Y S E: OTH

- Really Cool Music Releases Its Fourth Single - "So Many Lost Years"

- MGN Logistics Acquires Fast Service LLC, Fueling MyMGN Marketplace Expansion and Supercharging Expedited Coverage Nationwide

- The Wait is Over: Salida Wine Festival Announces Triumphant 2026 Return After Seven-Year Hiatus

- Graduates With $40K in Student Debt Are Buying Businesses Instead of Taking Entry-Level Jobs

- Anne Seidman: Within the Lines