Trending...

- "Big Tech is Not Talking About Everyone Owning, Controlling & Monetizing Their Own Data in the AI Future, but Phinge is," Says its CEO Robert DeMaio

- Vent Pros Expands Operations into Arizona to Meet Growing Demand for Commercial Ventilation and Kitchen Hood Cleaning Services

- Ski Safety Awareness Month highlights why seeing clearly and wearing modern protection matters more than ever

This breakthrough project will leverage nanotechnologies to improve heat transfer rates, higher complexity of internal design and inclusion of sensing and data transfer capabilities for condition and structural health monitoring and process control

PORTO SALVO, Portugal - nvtip -- Metal Additive Manufacturing (AM) technologies versatility makes them most suitable for producing from unique parts up to full series production. Yet, even the mostly used Metal AM (MAM) technology, Powder Bed Fusion (PBF), is not capable of going beyond single materials, and even the range of standard alloys is rather small. The MULTI-FUN project aims to address those shortcomings in two ways. First, by improving performance and efficiency in metal additive manufacturing through the integration of multi-functionalities based on novel active materials and the development of new structural materials for Wire Arc Additive Manufacturing (WAAM), including high strength aluminium alloys and low alloyed steel grades. And secondly by enabling multi-material design in geometrically complex 3D parts without being hindered by size.

The project focuses on Metal Additive Manufacturing by applying combinations of different materials, combined with the most appropriate AM technology for the deposition, to maximize the benefits. Wire and powder based directed energy deposition (DED) and material jetting are employed in new AM equipment combining different AM technologies with tailored software. The inclusion of nano-materials allows the integration of novel and breakthrough features, such as heat sink materials with the highest thermal conductivity, a high degree of integral design that makes it possible to embed electrical conductors in complex shaped metal structures, and the addition of sensing and data transfer capabilities to the equipment and software development. In addition, the integration of tailored optical fibres will enable bringing advanced thorough sensing capabilities to the manufactured parts to perform Structural Health Monitoring (SHM).

An ambitious project to broaden the scope of usage for metal additive manufacturing

The project has a total of four science and technology objectives. The first objective pertains to the development of five new materials customized for additive manufacturing, with a minimum of three of them using nanotechnology. This will allow for the creation of new products by maximizing thermal conductivity, minimizing electrical conductivity and/or improving wear resistance of metals. As a result of this objective, the development of new products is expected thanks to the advanced structural metals and corresponding active material solutions for innovative multiple functionalities. The second addresses new processes and it entails the development of Additive Manufacturing equipment and software to produce the requested material compositions during the layer build-up. In total, at least 10 new material combinations applying 5 new materials will be shown by the 7 demonstrators for different applications. The expected result is an innovative additive manufacturing equipment that integrates several additive manufacturing technologies working in parallel.

More on nvtip.com

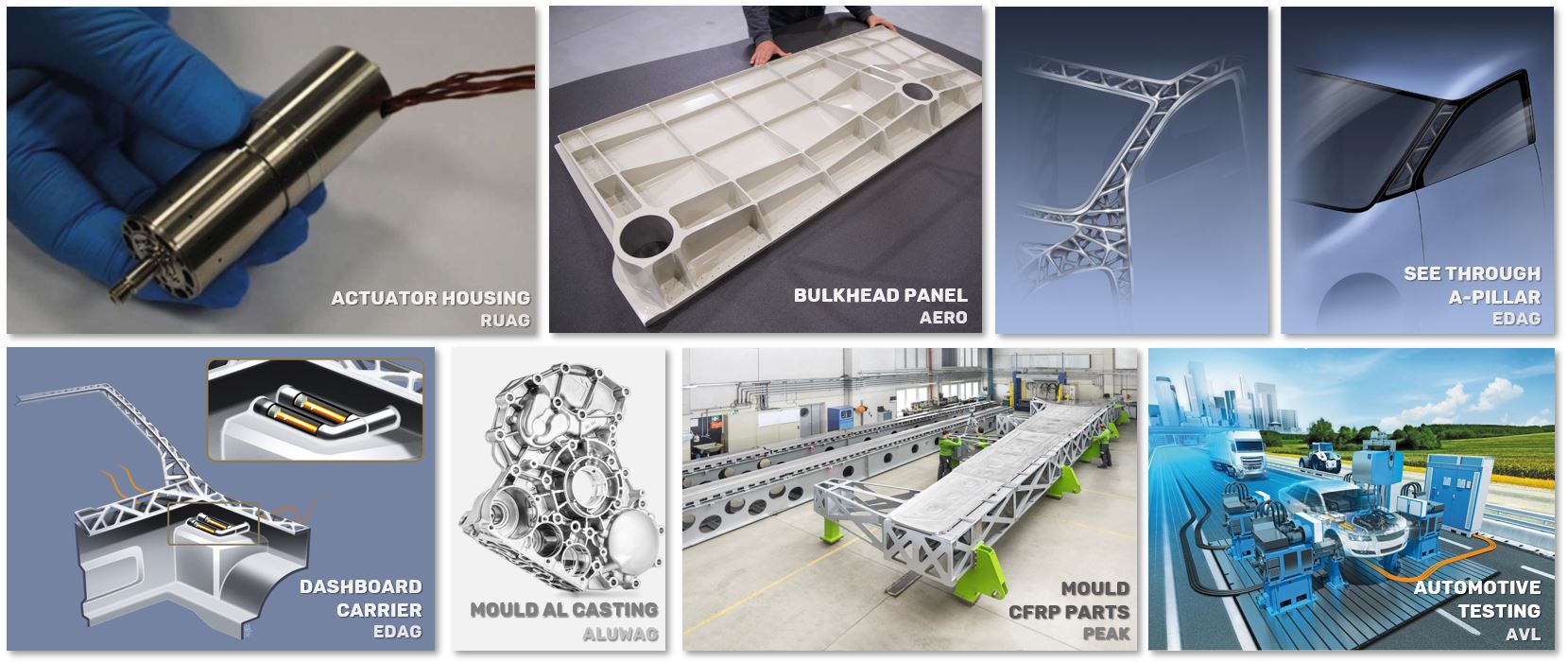

The third science and technology objective aims to manufacture and evaluate 7 physical

demonstrators with multi-material design and integrated multi-functionalities, for 3 use cases (structural parts, molds, test equipment), addressing 4 different markets (automotive, aviation, space and production industry). The expected end result is related to new methods and it will contribute to the development of new knowledge on increased efficiency of parts & molds due to integrated, multimaterial-based functions. The last objective relates to the constant assessment and improvement through a feedback loop of the reduction of environmental and economic impact, by evaluating additive manufacturing materials, hardware, process strategy and demonstrator design. The expected key result from this objective relates to new standards and it will enhance knowledge and

contribute to standards and support regulatory bodies adapting to multi-material additive

manufacturing.

The expected impact will be felt mani-fold. The defined KPIs fall into three main groups, including:

Project partners

This three-year project brings together a total of twenty-one partners from eight countries – Austria, Switzerland, Germany, Spain, United Kingdom, Poland, Portugal and Belgium. sets a clear focus on market-creating innovation, developing advanced materials and equipment for Additive Manufacturing of multi-material parts. Leading experts in AM process & equipment manufacturing (from SMEs, IND, RTOs and UNIV) will fully cover the physical integration of these advanced materials into metallic substrates.

Consortium members include:

Austria: LKR Leichtmetallkompetenzzentrum Ranshofen GmbH (www.ait.ac.at/en/lkr); voestalpine Metal Forming GmbH (https://www.voestalpine.com/group/en/divisions/metal-forming/); Inocon Technologie GmbH (https://www.inocon.at/); RHP Technology GmbH (https://www.rhp-technology.com/en); Peak Technology GmbH (https://www.peaktechnology.at/en/); Alpex Technologies GmbH (https://www.alpex-tec.com/de/willkommen-bei-alpex.html); AVL List GmbH (https://www.avl.com/)and RUAG Space GmbH (https://www.ruag.com/en). Belgium: European Federation for Welding, Joining and Cutting (https://www.ewf.be/). Germany: Deutsches Zentrum Fuer Luft – Und Raumfahrt EV, Institute of Materials Research (https://www.dlr.de/wf/en); Fraunhofer Gesellschaft Zur Foerderung der Angewandten Forschung E.V. (https://www.fraunhofer.de/); MIGAL.CO GmbH (https://www.migal.co/english/home/) and EDAG Engineering GmbH (https://www.edag-engineering.de/). Poland: INPHOTECH SP ZOO (https://inphotech.pl/). Portugal: Instituto de Soldadura e Qualidade – ISQ (https://www.isq.pt/). Spain: Fundation BCMaterials – Basque Centre for Materials, Applications and Nanostructures (https://www.bcmaterials.net/); LORTEK S COOP (http://www.lortek.es/) and Aerotecnic Metallic SL (https://www.aerotecnic.es/es/).

More on nvtip.com

Switzerland: Aluwag AG (https://www.aluwag.ch/). United Kingdom: Cranfield University (https://www.cranfield.ac.uk/) and WAAM3D Limited (https://waam3d.com/).

The MULTI-FUN project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 862617.

About the European Federation for Welding, Joining and Cutting

EWF is a pioneer in implementing a harmonized qualification and certification system for joining professionals. Through European projects EWF has been innovating in training methodologies and involved in the development of new technologies and uses for joining and additive manufacturing. Through its member organisations, EWF has established a firm link to the local industry, providing knowledge and training as well as participating in research initiatives that address the most pressing questions and challenges in the field of joining technologies.

More info at: www.multif-fun.eu

The project focuses on Metal Additive Manufacturing by applying combinations of different materials, combined with the most appropriate AM technology for the deposition, to maximize the benefits. Wire and powder based directed energy deposition (DED) and material jetting are employed in new AM equipment combining different AM technologies with tailored software. The inclusion of nano-materials allows the integration of novel and breakthrough features, such as heat sink materials with the highest thermal conductivity, a high degree of integral design that makes it possible to embed electrical conductors in complex shaped metal structures, and the addition of sensing and data transfer capabilities to the equipment and software development. In addition, the integration of tailored optical fibres will enable bringing advanced thorough sensing capabilities to the manufactured parts to perform Structural Health Monitoring (SHM).

An ambitious project to broaden the scope of usage for metal additive manufacturing

The project has a total of four science and technology objectives. The first objective pertains to the development of five new materials customized for additive manufacturing, with a minimum of three of them using nanotechnology. This will allow for the creation of new products by maximizing thermal conductivity, minimizing electrical conductivity and/or improving wear resistance of metals. As a result of this objective, the development of new products is expected thanks to the advanced structural metals and corresponding active material solutions for innovative multiple functionalities. The second addresses new processes and it entails the development of Additive Manufacturing equipment and software to produce the requested material compositions during the layer build-up. In total, at least 10 new material combinations applying 5 new materials will be shown by the 7 demonstrators for different applications. The expected result is an innovative additive manufacturing equipment that integrates several additive manufacturing technologies working in parallel.

More on nvtip.com

- CryptaBox Introduces a Hardware Crypto Cold Storage Wallet

- YWWSDC Launches AI-Native Digital Asset Infrastructure, Merging Technical Innovation with US-Standard Compliance

- High-End Exterior House Painting in Boulder, Colorado

- Simpson and Reed Co-Founders Shardé Simpson, Esq. and Ciara Reed, Esq. Launch "Hello Wilma,"

- Report Outlines Key Questions for Individuals Exploring Anxiety Treatment Options in Toronto

The third science and technology objective aims to manufacture and evaluate 7 physical

demonstrators with multi-material design and integrated multi-functionalities, for 3 use cases (structural parts, molds, test equipment), addressing 4 different markets (automotive, aviation, space and production industry). The expected end result is related to new methods and it will contribute to the development of new knowledge on increased efficiency of parts & molds due to integrated, multimaterial-based functions. The last objective relates to the constant assessment and improvement through a feedback loop of the reduction of environmental and economic impact, by evaluating additive manufacturing materials, hardware, process strategy and demonstrator design. The expected key result from this objective relates to new standards and it will enhance knowledge and

contribute to standards and support regulatory bodies adapting to multi-material additive

manufacturing.

The expected impact will be felt mani-fold. The defined KPIs fall into three main groups, including:

- First, the improvement of the efficiency, quality and reliability of the product by at least 40%;

- Secondly a better usage of raw materials and resources with reduced environmental impact and lowering costs by 35% as demonstrated by Life Cycle Assessment; and

- Lastly, it will provide new opportunities & business for SMEs across Europe, namely for the key players in advanced materials research in Additive Manufacturing.

Project partners

This three-year project brings together a total of twenty-one partners from eight countries – Austria, Switzerland, Germany, Spain, United Kingdom, Poland, Portugal and Belgium. sets a clear focus on market-creating innovation, developing advanced materials and equipment for Additive Manufacturing of multi-material parts. Leading experts in AM process & equipment manufacturing (from SMEs, IND, RTOs and UNIV) will fully cover the physical integration of these advanced materials into metallic substrates.

Consortium members include:

Austria: LKR Leichtmetallkompetenzzentrum Ranshofen GmbH (www.ait.ac.at/en/lkr); voestalpine Metal Forming GmbH (https://www.voestalpine.com/group/en/divisions/metal-forming/); Inocon Technologie GmbH (https://www.inocon.at/); RHP Technology GmbH (https://www.rhp-technology.com/en); Peak Technology GmbH (https://www.peaktechnology.at/en/); Alpex Technologies GmbH (https://www.alpex-tec.com/de/willkommen-bei-alpex.html); AVL List GmbH (https://www.avl.com/)and RUAG Space GmbH (https://www.ruag.com/en). Belgium: European Federation for Welding, Joining and Cutting (https://www.ewf.be/). Germany: Deutsches Zentrum Fuer Luft – Und Raumfahrt EV, Institute of Materials Research (https://www.dlr.de/wf/en); Fraunhofer Gesellschaft Zur Foerderung der Angewandten Forschung E.V. (https://www.fraunhofer.de/); MIGAL.CO GmbH (https://www.migal.co/english/home/) and EDAG Engineering GmbH (https://www.edag-engineering.de/). Poland: INPHOTECH SP ZOO (https://inphotech.pl/). Portugal: Instituto de Soldadura e Qualidade – ISQ (https://www.isq.pt/). Spain: Fundation BCMaterials – Basque Centre for Materials, Applications and Nanostructures (https://www.bcmaterials.net/); LORTEK S COOP (http://www.lortek.es/) and Aerotecnic Metallic SL (https://www.aerotecnic.es/es/).

More on nvtip.com

- Rande Vick Introduces Radical Value, Challenging How Brands Measure Long-Term Value

- Lisa Mauretti Launches Peace of Mind Travel Coaching to Guide Fearful Travelers to Discover the World with Confidence

- New Year, New Home: Begin 2026 at Heritage at South Brunswick

- Food Journal Magazine Releases Its 'Best Food In Los Angeles Dining' Editorial Section

- Enders Capital: 25% Gains with Just -0.80% Maximum Monthly Drawdown in Volatile Debut Year 2025

Switzerland: Aluwag AG (https://www.aluwag.ch/). United Kingdom: Cranfield University (https://www.cranfield.ac.uk/) and WAAM3D Limited (https://waam3d.com/).

The MULTI-FUN project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 862617.

About the European Federation for Welding, Joining and Cutting

EWF is a pioneer in implementing a harmonized qualification and certification system for joining professionals. Through European projects EWF has been innovating in training methodologies and involved in the development of new technologies and uses for joining and additive manufacturing. Through its member organisations, EWF has established a firm link to the local industry, providing knowledge and training as well as participating in research initiatives that address the most pressing questions and challenges in the field of joining technologies.

More info at: www.multif-fun.eu

Source: EWF

0 Comments

Latest on nvtip.com

- Acmeware and Avo Partner to Bring Real-Time Data Integration to MEDITECH Customers

- Health Force One Launches Clinical Workforce for Statewide RPM and RTM Programs

- New Analysis Reveals Most Patients Discontinue Weight Loss Drugs Within First Year

- Phinge CEO Robert DeMaio Reflects on His Observations After CES & How User Data Ownership & Hardware Based Verification is the Only Way Forward in AI

- Why Aerie Resort Is a Must-Stay When Visiting Zion National Park

- International Law Group Expands Emergency Immigration Consultations for Somali Minnesotans Amid ICE Actions

- Premium Bail Bonds Proudly Sponsors BOFAB BBQ Team at the 2026 Lakeland Pigfest

- UK Financial Ltd Receives Recognition In Platinum Crypto Academy's "Cryptonaire Weekly"

- P-Wave Press Announces Pushing the Wave 2024 by L.A. Davenport

- Preston Dermatology & Skin Surgery Center Wins Gold and Bronze in Prestigious Annual DIAMOND Awards

- David Boland, Inc. Awarded $54.3M Construction Contract by U.S. Army Corps of Engineers, Savannah District

- "Phinge Unveil™" Coming to Las Vegas to Showcase Netverse Patented Verified App-less Platform, AI & Modular Hardware Including Developer Conferences

- Elizabeth McLaughlin, Founder and CEO of Red Wagon Group, named 2026 Presidential Leadership Scholar

- U.S. Congressional Candidate Peter Coe Verbica on America's Asymmetric Crisis

- Jones Sign Rebrands as Jones to Reflect Growth, Innovation, and Expanded Capabilities

- $1 Million Share Repurchase Signals Confidence as Off The Hook YS Scales a Tech-Driven Platform in the $57 Billion U.S. Marine Market

- Trends Journal's Top Trends of 2026

- CollabWait to Launch Innovative Waitlist Management Platform for Behavioral Health Services

- Urban Bush Women Celebrates Bessie Award Nominations & Winter 2026 Touring

- Imagen Golf Launches "Precision Lessons" with Trackman iO in Newtown, PA