Trending...

- Entering 2026 with Expanding Footprint, Strong Industry Tailwinds, and Anticipated Q3 Results: Off The Hook YS Inc. (N Y S E American: OTH)

- Super League (N A S D A Q: SLE) Enters Breakout Phase: New Partnerships, Zero Debt & $20 Million Growth Capital Position Company for 2026 Acceleration

- Tiger-Rock Martial Arts Appoints Jami Bond as Vice President of Growth

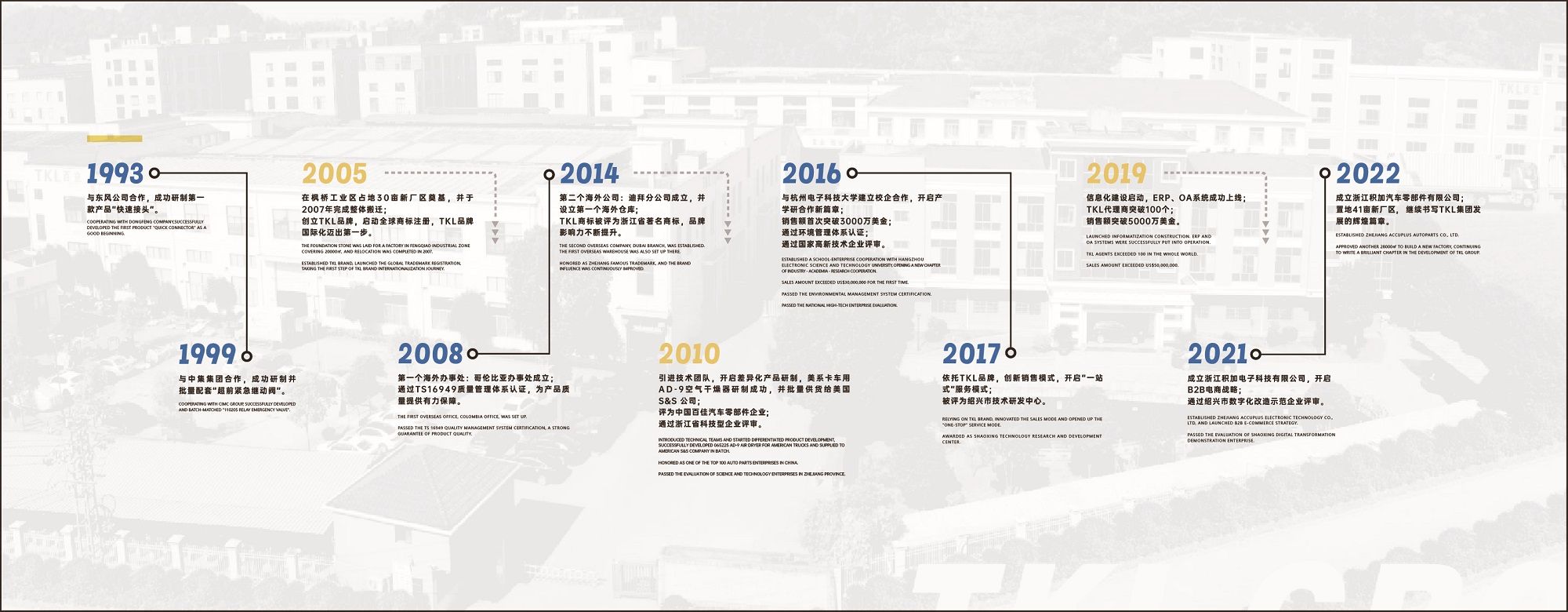

SHAOXING, China - nvtip -- TKL Group officially opened its new factory in Zhuji, China on 2025. The new facility provides expanded development space and more advanced facilities, further enhancing our service capabilities and innovation. TKL, already a major supplier to Meritor-Wabco, Haldex, and Fleetpride, currently produces 6 million units annually. Upon opening of the new facility, this capacity will reach 10 million units.

Looking back at our development history,from humble beginnings in a mountain village workshop to a global braking systems leader operating across 67 countries, TKL epitomizes the resilient ascent of "Made in China" through relentless innovation.Recognized as one of China's Top 100 Automotive Parts Suppliers and a National High-Tech Enterprise, we are redefining commercial vehicle safety standards worldwide, driving the "Made in China" initiative forward with groundbreaking technologies.

Over the past decade,our evolution from single chassis brake components to integrated system-level solutions has been fueled by deep expertise in the North American commercial vehicle market,specifically the heavy-duty truck segment.Guided by our "Deep Technology + Broad Service" strategy,TKL now emerges as the aftermarket's premier integrated supplier of full life-cycle support services.

Technological Innovation: Micron-Level Security Moat

In TKL's 43,000㎡ digital factory, 150 intelligent devices constitute a precision manufacturing matrix. Within a Class 10,000 dust-free workshop environment, vacuum leak sealing technology surpasses conventional industry limits, metal oxidation processes achieve significant enhancement in material performance, and 2μm-level three-coordinate detection ensures high-precision manufacturing. Millions of simulation operations are conducted to validate product reliability. The quality control standards implemented are substantially higher than industry benchmarks. The digital workshop, completed in 2022, enables real-time order tracking through 5G and industrial Internet integration, signifying TKL's transition from traditional manufacturing to digital and intelligent manufacturing.

More on nvtip.com

Mode Upgrade: From Truck Parts Wholesale to System Solutions

By breaking through the limitations of single-product competition, TKL aggregated and integrated resources from 200 core suppliers, establishing a truck parts wholesale product matrix of over 10,000 types,and equipped with the integration capabilities across four key vehicle systems: braking,chassis, transmission, and body. Innovate the "product supermarket + technical manager" model to provide customers with customized solutions covering the entire vehicle's needs, and fulfill the value commitment of "saving time, effort, and cost".

Global Expansion: Operations in 67 Countries Highlight China's Manufacturing Strength

From dominating the heavy truck market in North America to supplying specialized vehicles for oil fields in the Middle East, and from supporting operations in the rain forests of South America to meeting stringent environmental standards in Europe, TKL's product matrix has continuously expanded across the globe, enhancing the international presence of the TKL brand in 67 countries. The establishment of three major technical service centers in the United States, Colombia, and the United Arab Emirates has successfully integrated "Chinese solutions" with localized service capabilities.

Service Innovation: Pain Points Drive the Innovation Ecosystem

Guided by the customer-centric philosophy of "ensuring safe and timely arrival",TKL has developed a comprehensive digital service system. This includes a real-time order tracking ERP system, intelligent warehousing enabling just-in-time (JIT) distribution, and a globally responsive technical team capable of on-site support within 72 hours. As the market enters a phase of full-scale competition, TKL has achieved value transformation through its "one-stop packaged service" model.

More on nvtip.com

From a manufacturer of individual braking components to a fully integrated supplier, TKL has demonstrated over the past three decades that Chinese manufacturing enterprises are capable not only of breaking through technological barriers but also of reshaping the logic of industrial value distribution. Moving forward, we are committed to serving a broader customer base and fulfilling our mission of being customer-centric, delivering comprehensive automotive parts system solutions, and maximizing value creation for our clients.

Finally, we would like to thank all our customers and partners for their continued support and trust. We look forward to working with you all to create an even brighter future at a new starting point.

Contact:

www.tkltruckparts.com

export@tkltruckparts.com

Looking back at our development history,from humble beginnings in a mountain village workshop to a global braking systems leader operating across 67 countries, TKL epitomizes the resilient ascent of "Made in China" through relentless innovation.Recognized as one of China's Top 100 Automotive Parts Suppliers and a National High-Tech Enterprise, we are redefining commercial vehicle safety standards worldwide, driving the "Made in China" initiative forward with groundbreaking technologies.

Over the past decade,our evolution from single chassis brake components to integrated system-level solutions has been fueled by deep expertise in the North American commercial vehicle market,specifically the heavy-duty truck segment.Guided by our "Deep Technology + Broad Service" strategy,TKL now emerges as the aftermarket's premier integrated supplier of full life-cycle support services.

Technological Innovation: Micron-Level Security Moat

In TKL's 43,000㎡ digital factory, 150 intelligent devices constitute a precision manufacturing matrix. Within a Class 10,000 dust-free workshop environment, vacuum leak sealing technology surpasses conventional industry limits, metal oxidation processes achieve significant enhancement in material performance, and 2μm-level three-coordinate detection ensures high-precision manufacturing. Millions of simulation operations are conducted to validate product reliability. The quality control standards implemented are substantially higher than industry benchmarks. The digital workshop, completed in 2022, enables real-time order tracking through 5G and industrial Internet integration, signifying TKL's transition from traditional manufacturing to digital and intelligent manufacturing.

More on nvtip.com

- Snell & Wilmer Attorney Caylye Nordling Joins Board of Directors of SafeNest

- EnergyStrat Launches Global LNG Risk Outlook 2025–2030

- Strong Revenue Gains, Accelerating Growth, Strategic Hospital Expansion & Uplisting Advancements: Cardiff Lexington Corporation (Stock Symbol: CDIX)

- Holiday Decorations Most Likely to Cause Injuries

- UK Financial Ltd Confirms Official Corporate Structure of the Maya Preferred Project and Its Dual-Class Token System

Mode Upgrade: From Truck Parts Wholesale to System Solutions

By breaking through the limitations of single-product competition, TKL aggregated and integrated resources from 200 core suppliers, establishing a truck parts wholesale product matrix of over 10,000 types,and equipped with the integration capabilities across four key vehicle systems: braking,chassis, transmission, and body. Innovate the "product supermarket + technical manager" model to provide customers with customized solutions covering the entire vehicle's needs, and fulfill the value commitment of "saving time, effort, and cost".

Global Expansion: Operations in 67 Countries Highlight China's Manufacturing Strength

From dominating the heavy truck market in North America to supplying specialized vehicles for oil fields in the Middle East, and from supporting operations in the rain forests of South America to meeting stringent environmental standards in Europe, TKL's product matrix has continuously expanded across the globe, enhancing the international presence of the TKL brand in 67 countries. The establishment of three major technical service centers in the United States, Colombia, and the United Arab Emirates has successfully integrated "Chinese solutions" with localized service capabilities.

Service Innovation: Pain Points Drive the Innovation Ecosystem

Guided by the customer-centric philosophy of "ensuring safe and timely arrival",TKL has developed a comprehensive digital service system. This includes a real-time order tracking ERP system, intelligent warehousing enabling just-in-time (JIT) distribution, and a globally responsive technical team capable of on-site support within 72 hours. As the market enters a phase of full-scale competition, TKL has achieved value transformation through its "one-stop packaged service" model.

More on nvtip.com

- CCHR Florida Joins Global Call to Ban Electroshock Treatment, Citing New Evidence of Widespread Patient Harm

- BoxingRx Announces Full Gym Renovation Ahead of New Ownership's One-Year Anniversary

- UK Financial Ltd Announces It's Official Corporate Headquarters In The United Kingdom

- Rigani Press Announces Breakthrough Book for Health IT and Medical Leaders to Forge the Road to Responsible AI

- FreeTo.Chat - The bold, Anonymous Confession Platform, ushers in a new era of tension relief

From a manufacturer of individual braking components to a fully integrated supplier, TKL has demonstrated over the past three decades that Chinese manufacturing enterprises are capable not only of breaking through technological barriers but also of reshaping the logic of industrial value distribution. Moving forward, we are committed to serving a broader customer base and fulfilling our mission of being customer-centric, delivering comprehensive automotive parts system solutions, and maximizing value creation for our clients.

Finally, we would like to thank all our customers and partners for their continued support and trust. We look forward to working with you all to create an even brighter future at a new starting point.

Contact:

www.tkltruckparts.com

export@tkltruckparts.com

Source: TKL GROUP

0 Comments

Latest on nvtip.com

- Coalition and CCHR Call on FDA to Review Electroshock Device and Consider a Ban

- Spark Announces 2025 Design Award Winners

- NEW Luxury Single-Family Homes Coming Soon to Manalapan - Pre-Qualify Today for Priority Appointments

- Dominic Pace Returns to the NCIS Franchise With Guest Role on NCIS: Origins

- Anderson Periodontal Wellness Attends 5th Joint Congress for Ceramic Implantology

- UK Financial Ltd Completes Full Ecosystem Conversion With Three New ERC-3643 SEC-Ready Tokens As MCAT Deadline Closes Tonight

- AI Real Estate Company Quietly Building a National Powerhouse: reAlpha Tech Corp. (N A S D A Q: AIRE)

- Inkdnylon Expands National Uniform Embroidery Services

- Appliance EMT Expands Appliance Repair Services to Portland, OR and Vancouver, WA

- Next Week: The World's Best Young Pianists Arrive in Music City for the 2025 Nashville International Chopin Piano Competition

- Revenue Optics Builds Out Its Dedicated Sales Recruiting Firm with Strategic Addition of Christine Schafer

- Hydrofast Elevates the Holiday Season: The C100 Countertop RO System Merges Smart Tech with Wellness for the Perfect Christmas Gift

- Phinge CEO to Unveil Verified Robotics Ensuring Unprecedented Safety & Exclusive Owner Control Thru its Netverse Patented App-less Tech, AI & Hardware

- Melospeech Inc. Accepts Nomination for HealthTech Startup of the Year

- Flower City Tattoo Convention Draws Record Attendance in Rochester, NY

- KIKO NATION TOKEN (Official Release)

- Verb™ Presents Features Vanguard Personalized Indexing: Utilizing Advanced Tax-Loss Harvesting Technology

- Luckygirl Bodywork Opens in Silverado Park Place Area

- UK Financial Ltd Announces A Special Board Meeting Today At 4PM: Orders MCAT Lock on CATEX, Adopts ERC-3643 Standard, & Cancels $0.20 MCOIN for $1

- 6 Holiday Looks That Scream "Old Money" But Cost Less Than Your Christmas Tree